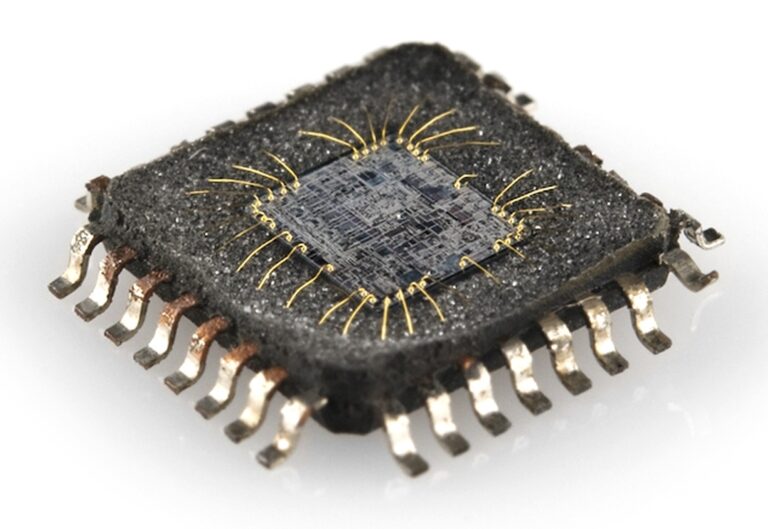

Electronics use integrated circuits (ICs), often called semiconductor chips or microchips. It’s amazing how useful these tiny treasures are.

IC chips are formed of pieces that work together to perform electronic operations. Transistors, diodes, resistors, and capacitors are made from tiny silicon pieces.

To understand how IC chips power modern devices, you must know how their parts join together. We’ll discuss integrated circuits and modern technology.

The Evolution of IC Chips

IC chips have transformed technology over time. Integrating circuits have evolved from simple to complicated in modern electronics.

Since their late 1950s debut, these chips have evolved from simple circuits to intricate elements that fuel our technology. Integrated circuits are employed in many things, from computer microprocessors to medical device monitoring.

Modern IC chips are utilized for many things. They’re in automobiles, smartphones, appliances, and space research gear. Flexible and efficient, these chips are crucial to 21st-century technologies.

Understanding IC Chip Types

You may need to know the types of IC chips to choose the best one for your electronics. Digital, analog, mixed-signal, and power control ICs have diverse functions.

For digital signals and data, computers and smartphones need digital IC chips. However, analog IC chips handle constant data like temperature and sound. Due to their dual architecture, some integrated circuits (ICs) can handle digital and analog data well. Rantle is one of the leading companies which are offering all these kinds of IC chips.

Controlling power ICs control power sources in electronics, ensuring they perform properly and spend little energy. Learn about these IC chips to make wise electrical system building and repair decisions.

The Manufacturing Process Behind IC Chips

IC chips are made through cutting-edge fabrication methods in a process that is very complicated and detailed. Over the years, chip processing methods have improved, pushing the limits of what is possible in semiconductor manufacturing.

Anyone who wants to understand how complex current technology works needs to know how IC chips are made. Every step in the manufacturing process, from lithography to etching, is very important to how the end product turns out.

In semiconductor manufacturing, one can appreciate the accuracy and knowledge needed to make these tiny but powerful components. Wafer processing methods are always changing, which is what keeps the industry moving forward and makes it possible for IC chips to get smaller, faster, and more efficient.

The Future of IC Chips

ICs’ future is full of exciting new ideas and advancements. Our gadget chips’ technologies vary with technology. Advanced integrated circuit packaging technologies are expanding, speeding, and improving semiconductors. These new ideas allow AI to play a large role in chip manufacturing.

As the Internet of Things (IoT) grows, more devices and systems are using microchips. In addition to making connections easier, this connectivity is enabling new data processing and automation methods.

As we move ahead to IC chips, these new concepts and trends will continue to revolutionize the semiconductor industry, making integrated circuit technology stronger and more adaptable.

Conclusion

Modern technology relies on IC chips or integrated circuits. IC chips power modern innovations in cell phones and medical devices. These tiny yet powerful components boost device processing, memory, and usefulness.

The use of IC chips can transform products and services, improving efficiency, dependability, and innovation. IC chips can boost business growth by optimizing supply chains or improving communication networks.

In conclusion, companies that want to stay ahead in the constantly shifting tech scene have to adopt IC chips. By using these little yet powerful components, industries can unleash new possibilities and create future-changing technology.